In modern industries across Schweiz, automation plays a key role. One of the most important tools in this space is PLC software. PLC stands for Programmable Logic Controller. It is a type of software used to control machines and processes in factories. Unlike regular software, PLC software works with machines in real-time. It helps machines know what to do and when to do it, all with great accuracy.

PLC software is used in many industrial fields in Schweiz because it allows for smooth and steady operations. Whether it’s moving a robotic arm or adjusting temperature in a processing line, this software makes it happen automatically. As factories and industrial setups become more advanced, PLC software is also evolving to meet new needs. Swiss companies are turning to this technology to stay efficient and competitive in the global market.

What PLC Software Means

PLC software is a special kind of software that helps machines work by following a set of instructions. It is installed on a device called a programmable logic controller. This device is connected to machines and sensors. When something happens, like a button being pushed or a temperature reaching a set point, the PLC tells the machine what to do next.

This type of software is very important in making sure machines work correctly and safely. It replaces the need for someone to control machines by hand. In Schweiz, where industries rely on precision and quality, PLC software helps keep everything running the right way. It is like the brain of the machine, making smart decisions based on the data it receives.

Why It Matters for Industrial Growth

PLC software is helping Swiss industries grow faster and smarter. Instead of relying only on human workers, companies can use machines that follow software instructions. This reduces mistakes and improves output. For example, in food processing, machines controlled by PLC software can measure and pack food without missing a beat.

Swiss industries are known for being reliable and clean. PLC software adds to this strength by helping companies meet high-quality standards. It also makes it easier to track what happens at each step of the process. This kind of automation is not just about speed but also about making sure everything is done right.

Where PLC Software Is Used in Schweiz

PLC software is widely used in many sectors across Schweiz. From large factories to small equipment units, this tool is everywhere behind the scenes. The two main areas where PLC software plays a huge role are manufacturing and the energy sector.

Use in Manufacturing and Engineering

In Swiss manufacturing, machines need to be smart and quick. PLC software helps machines do their tasks without needing much human help. For example, in a car parts factory, machines controlled by PLC software might drill holes, paint surfaces, or place parts together. Each task happens exactly when and how it should.

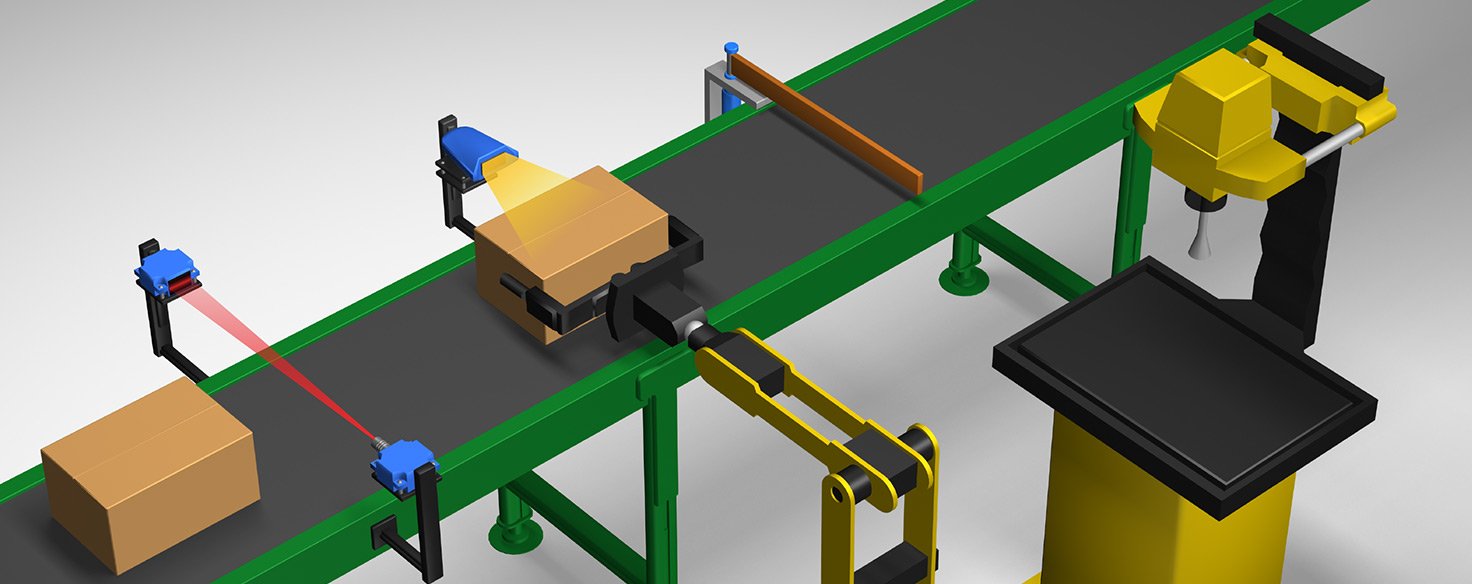

Engineering companies in Schweiz also use PLC software to create systems that are both safe and efficient. It can control conveyor belts, robotic arms, and sorting machines. With this software, machines follow instructions without delay, which makes the entire production line more reliable. Because of this, Swiss-made products continue to be known for high quality around the world.

Role in Energy and Infrastructure

PLC software is also used in the energy industry in Schweiz. It helps control water pumps, electricity grids, and even traffic lights. These are important parts of the infrastructure that need to work all the time. With PLC software, Swiss cities and towns can run smoothly without interruption.

In power stations, PLC software manages the flow of electricity and ensures everything is working safely. In water treatment plants, it controls pumps and valves to clean water efficiently. This kind of software is important for keeping vital services up and running. It gives engineers a way to control large systems easily and respond quickly when something goes wrong.

Key Benefits of PLC Software for Swiss Companies

Swiss companies gain many benefits by using PLC software. The most important advantages are higher productivity and better control over machines. These help businesses stay ahead in a competitive market.

Improved Productivity and Precision

PLC software helps machines do their job faster and more accurately. For example, in a packaging line, the software makes sure each box is filled, sealed, and labeled correctly. This speeds up the work and reduces waste. It also ensures that all products meet the same high standard.

This kind of precision is important in Switzerland, where customers expect top-quality products. With PLC software, companies can make sure every product is made the same way, every time. That makes production faster and more reliable, helping Swiss industries grow.

Better Monitoring and Control

With PLC software, managers can see how machines are working in real time. They can track performance, find errors, and make changes from a central control room. This makes it easier to keep everything running smoothly.

If a problem happens, the software can send a warning or even stop the machine before damage happens. This helps keep workers safe and protects expensive equipment. In Switzerland, where safety and quality are top priorities, these features are especially valuable.

Challenges in Using PLC Software in Schweiz

Even though PLC software has many advantages, there are also challenges that companies in Schweiz face. These include setup costs and the need for skilled workers.

High Setup and Maintenance Costs

Installing PLC systems can cost a lot of money. Companies need to buy the right equipment, hire experts, and train staff. This can be hard for smaller businesses that don’t have big budgets. Also, if the software or hardware breaks, fixing it can take time and money.

Because of this, some businesses are slow to switch to PLC systems. They may worry about the cost or how long it will take to see benefits. Planning ahead and starting with small steps can help make the change easier and more affordable.

Skill Gaps and Technical Training

To use PLC software well, companies need skilled workers who understand how it works. Not every technician knows how to program or fix PLC systems. This means businesses need to invest in training.

Finding workers who already know about PLC software can be hard, especially in small towns. To fix this, some companies in Schweiz are working with schools and training centers to teach these skills early. This helps build a future workforce that is ready for automation.

Future Trends of PLC Software in the Swiss Market

As technology keeps improving, PLC software is getting smarter. In Schweiz, the future looks bright for this kind of automation. Two key trends to watch are smart system integration and growing local support.

Integration with Smart Systems

New PLC software is being designed to work with smart systems and the Internet of Things (IoT). This means machines can talk to each other and share data in real time. For example, if a machine sees a problem, it can alert another system to slow down or stop. This helps prevent problems before they get worse.

Swiss companies are starting to use these smart features to make their operations even better. They can see more data, make faster decisions, and improve every part of their work. This kind of future technology will help Swiss businesses stay global leaders in automation.

Growth of Local Tech Support

As more Swiss businesses use PLC software, local tech companies are stepping up to help. They offer support, training, and custom solutions for businesses of all sizes. This local help makes it easier for companies to start using automation without big delays or high costs.

With strong local support, Swiss companies can try new ideas and grow faster. Whether it’s a small startup or a large factory, everyone can benefit from the growing network of PLC experts in the country.

Conclusion

PLC software is becoming an important part of industrial life in Schweiz. It helps machines work better, faster, and with fewer mistakes. From factories to energy plants, this software plays a big role in making things run smoothly. While there are some challenges, like high setup costs and skill shortages, Swiss companies are finding smart ways to overcome them. With the support of local tech providers and a strong focus on quality, PLC software will continue to shape the future of automation in Schweiz. Businesses that invest in this technology today will lead the way tomorrow.